CMS Series

Reliable and Efficient Solutions for 95.0 to 99.9% purity

Its wide and versatile usage makes compressed air a vital component of commercial production.

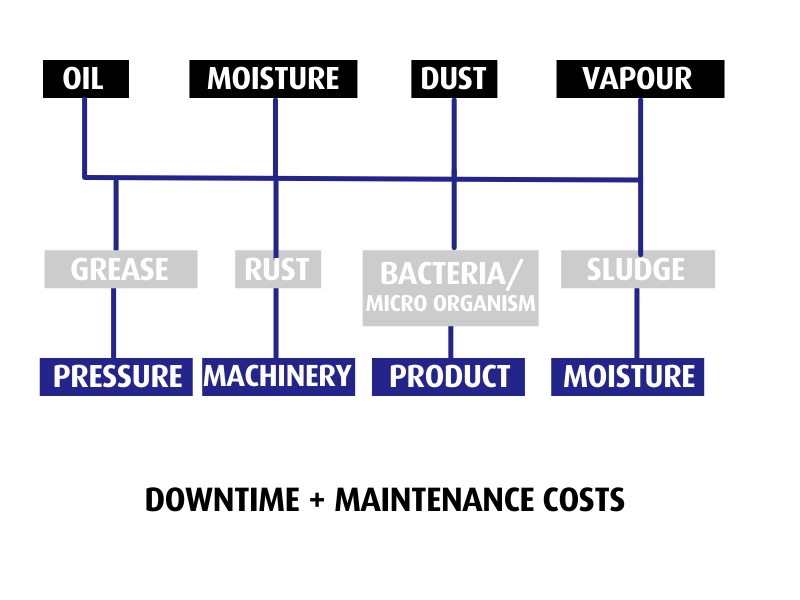

Standard industrial air dryers are not suited to eliminate vapour moisture, and this results in the formation of sludge, scale, pitting, and bacteria. These contaminants cause both long and short term damages to your semiconductors, electricals, mechanical equipment, pipelines and product. Water (condensate and vapour) causes the greatest damage in the form of corrosion in industrial processes. But apart from vapour moisture, compressed air has the following contaminants:

Rising maintenance costs, expensive and unnecessary spares, production downtime and long-term capital expense are common issues.

If the compressed air comes in contact with the product (process air), untreated air can contaminate it, leading to increasing rejection costs and thereby increasing costs for solutions also.

Pipelines carrying the untreated compressed air also contribute to increased costs due to scale formation and shortened life.

Capital: The air compressor comprises the major cost.

Oil-free compressors are substantially more expensive than oil lubricated compressors.

Power: Power usage is the highest cost in the lifetime of a compressed air system. An efficient compressed air system will ensure high utility of the compressor. A key factor in controlling power expense is the purge loss factor of the system.

For example, if a compressed air system generates 100 CFM of compressed air and has 12% purge loss, that means the user only gets 88 CFM air at the outlet of the system for actual use.

Maintenance: Here, maintenance is not just of the air system but also of the pneumatic equipment, product, pipeline that are associated with the compressed air. If the air is wet and improperly treated, all related maintenance costs will go up.

Breakdown: Similar to maintenance, the breakdown cost is tied with the equipment/product/pipeline. A breakdown in the air system could lead to production downtime, spoilage of product and failure of pneumatic equipment.

Your air compressor will work best when kept in a clean and cool environment. The more pollutants in the surroundings, the faster your compressor health declines.

Purge air is clean and dry compressed air that is used to regenerate the CAT Unit. Compared to industry standards (15-25%), the CAT requires only 2-3% of purge air.

You can get Packaged Compressed Air Solution with adsorbtech. We are offering complete A-Z solution from Compressor, Receivers, CAT Unit, piping and valving.

No other dryer or filter is needed after installed adsorbtech Compressed Air Solution.

We at adsorbtech realize that even after installing the most expensive of filters & dryers, compressed air contaminants are not truly eliminated. The magnitude of the problem increases manifold during monsoon / winter or during high humidity in the summer season.

The pipeline length, air conditioned environments, rain or sun do not affect the Compressed Air Treatment ‘CAT’ Unit.

Implementing our immense experience in the field, we have created a solution, with in-house R&D, that delivers dry air at usage point.

Explore the CAT Unit: Unique concept that delivers dry air @ usage point.

Explore the CAT System: Turnkey system and one-stop approach to your compressed air needs.

Explore Compressed Air Leasing Solutions: Cut free from all compressed air operations for a fixed monthly cost.

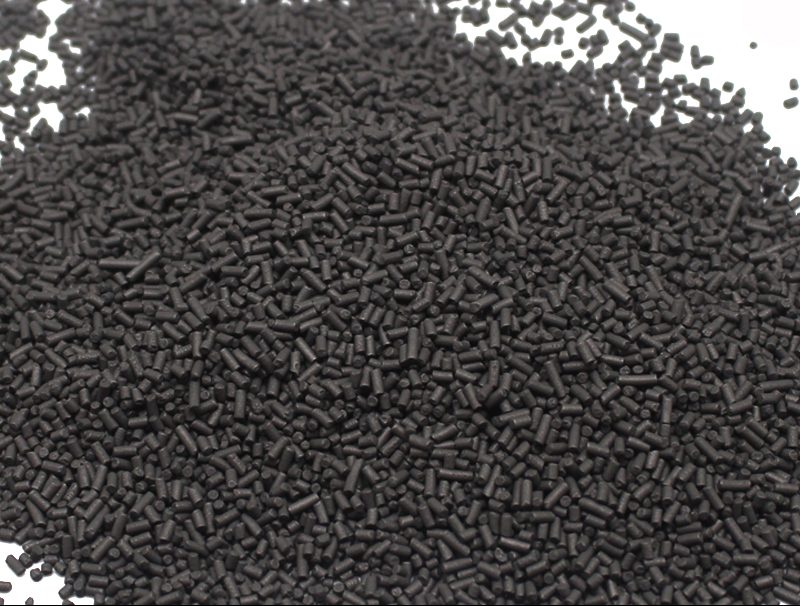

Reliable and Efficient Solutions for 95.0 to 99.9% purity

Catering to Nitrogen-Ammonia gas mixture requirements

Adsorbtech Innovation for Uninterrupted Nitrogen supply

Trusted solution for Heat Treatment and sensitive applications

Authorized Adsorbtech spare parts for long life and efficiency

Designed for upto 40 Bar pressure

Connect with us and meet your compressed air requirements today