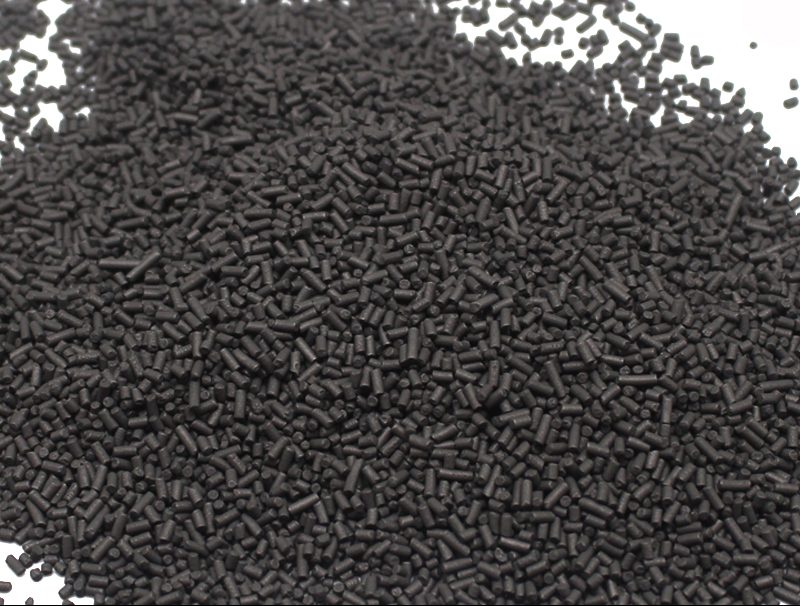

CMS Series

Reliable and Efficient Solutions for 95.0 to 99.9% purity

Adsorbtech PDx Series is specifically designed for applications that require either pure Nitrogen Gas (99.99995% or 0.50 ppm), and Hydrogen gas as per the application. The PDx Series utilizes Ammonia gas (NH3) to attain such high gas purity levels as it is commercially and technically unviable to generate 0.5 ppm pure Nitrogen directly from Compressed Air. Based on PSA technology and integrated with an Ammonia Cracking Furnace, Adsorbtech PDx Series is the safest and most efficient partner for your Nitrogen and Nitrogen-Hydrogen gas requirement. Each unit is customized to meet your exact parameters.

We well understand the importance of instrument accuracy in such high purity gas applications. Thus, we developed Adsorbtech Gas Analyzers that have a least count of 0.01 ppm to assure our clients of continuous and on-line N2 purity.

Save expensive floor space

With online monitoring

Tailor-made for your application

Zero Accidents to Date

Save on manpower

Long-term savings

| Gas Composition | PDx Series |

|---|---|

| Nitrogen | 99.99 to 99.9999% |

| Oxygen | 0.01 to 0.0001 % (or 1 PPM) |

| Hydrogen / Cracked Ammonia | As per requirement |

| Pressure | 0.5 to 60 kg/cm2g |

| Dew Point | (-) 60 to (-) 80℃ |

No additional space needed

For 24/7/365 fail-proof gas supply

Unique Feature : Call us to know more

Our expertise and deep understanding of Heat Treatment applications has led to the safe, aesthetic and efficient development of the PDx Series.

We are the most trusted choice for several applications, processes and industries.

Reliable and Efficient Solutions for 95.0 to 99.9% purity

Catering to Nitrogen-Ammonia gas mixture requirements

Adsorbtech Innovation for Uninterrupted Nitrogen supply

Trusted solution for Heat Treatment and sensitive applications

Authorized Adsorbtech spare parts for long life and efficiency

Designed for upto 40 Bar pressure

Connect with us and meet your compressed air requirements today