CMS Series

Reliable and Efficient Solutions for 95.0 to 99.9% purity

Compressed air is used in almost all industries for various applications. Using pure and dry compressed air in all applications is vital to gain several economic benefits. A deep understanding of the users processes has led us to valuable insights and significant product development. The Adsorbtech CAT Series is a robust and integral teammate of several such processes.

Each Compressed Air application is as unique as you are.

And so, each application requires a tailor-made solution to meet your exact requirements. Our team of Air Experts works with you to deliver the best suited CAT which delivers pure air and maximizes savings in power and maintenance costs.

The most stringent of standards must be maintained for all pharmaceutical processes as the air often comes in contact with the product at various stages of production. The prerequisite of using highly expensive oil-free air compressors is proof of the high standards expected. If air is not treated correctly and consistently, problems like colour variation, blistering, cracks, or breaks can occur in tablets. There is the additional health risk if the compressed air has traces of moisture and oil.

With the expanding usage of automation, clean and dry compressed air has become increasingly important for the automotive industry. Expensive pneumatic grinders, CNC and VMC equipment need the best support for long term production gains. The cost efficiency of powder coating and spray painting is multiplied when dry air is used in the powder recovery process. Be it for tools, surface or the car body, the CAT Unit helps avoid rejection and operational costs with its consistent supply of pure and dry air at usage point.

There is extensive use of compressed air in food and beverage- conveying ingredients, packaging goods, cleaning and drying containers, sorting machines to name a few. Clean compressed air contributes to high-quality flavor in the production of certain goods such as ice cream. To protect the consumers and business, compressed air must be free of oil, moisture, particles and bacteria. Consistent pure and dry air ensures low product rejection and long life of expensive pneumatic components.

Production of chemicals involves creation of toxic, reactive and other reactive substances that often come in direct contact with compressed air. Thus, it is necessary to treat this air of any contaminants to ensure a safe working environment. Detergents, powders and other such synthetic raw materials require oil-free air to avoid losses. The presence of humidity/vapour moisture will lead to clumping of granules and thus increase production cost.

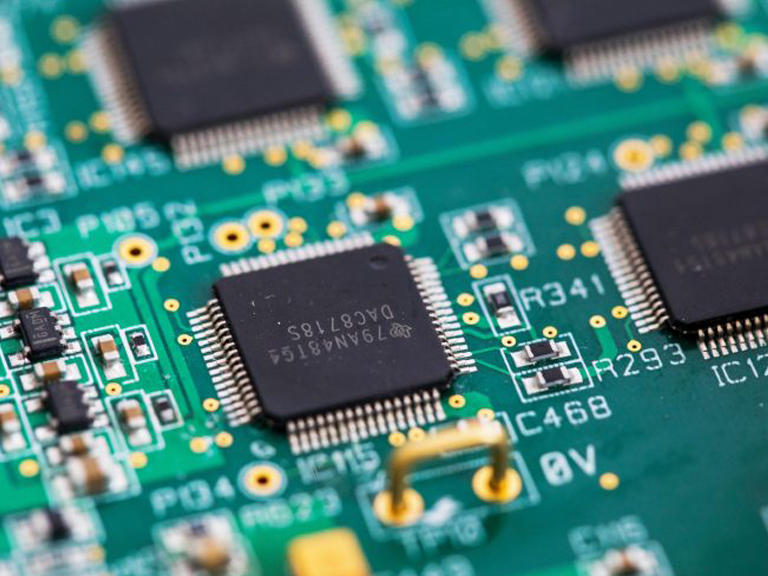

Capital heavy, sensitive and highly technical operations define the electronics industry. And at each stage, compressed air plays an important part. Now even more so with robotic pneumatic equipment. Presence of moisture and oil is unacceptable for the production as well as the consumer. Production of wafers, circuit boards, wires and processes like soldering are some of the applications that require Class 1 Air or above.

The compressed air applications in this segment are as diverse as the engineering industry. Compressed air plays a significant role in maintaining the cost-effective production processes in mechanical engineering. The list of machines and tools using compressed air is endless but we well understand the importance Adsorbtech CAT plays in all.

Both ferrous and non-ferrous metal manufacturing have various processes utilizing compressed air. We understand that the right quality compressed air can help you save downtime, product rejection and avoid scrap. The Adsorbtech CAT Series can deliver this and reduce energy and maintenance costs.

Compressed air is used in both man-made and natural textiles, and at nearly every stage of production. Significant raw material costs can be reduced with the correctly designed compressed air solution.

Remember, air is free but compressed air is not. Adsorbtech helps you save on compressed air costs. We also bring you peace of mind from daily challenges and utility costs that are part of all industries and applications. Contact Us to have your very own Compressed Air Treatment Solution. In case you do not see your specific application, Contact Us and we will set up a consultation.

Focus on your core areas of business with Adsorbtech Compressed Air Leasing Solutions.

Be independent of daily challenges such as:

Reliable and Efficient Solutions for 95.0 to 99.9% purity

Catering to Nitrogen-Ammonia gas mixture requirements

Adsorbtech Innovation for Uninterrupted Nitrogen supply

Trusted solution for Heat Treatment and sensitive applications

Authorized Adsorbtech spare parts for long life and efficiency

Designed for upto 40 Bar pressure

Connect with us and meet your compressed air requirements today