CMS Series

Reliable and Efficient Solutions for 95.0 to 99.9% purity

Nitrogen gas is extracted from the atmosphere, which consists of 78% Nitrogen. Adsorbtech Nitrogen Generators extract Nitrogen gas from the atmosphere using Pressure Swing Adsorption (PSA) technology.

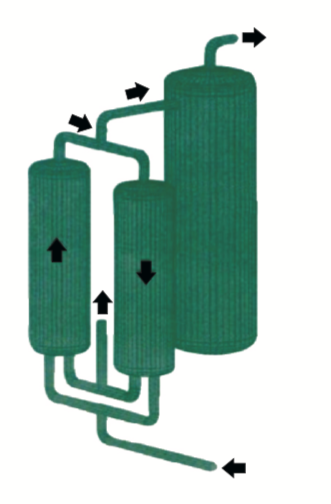

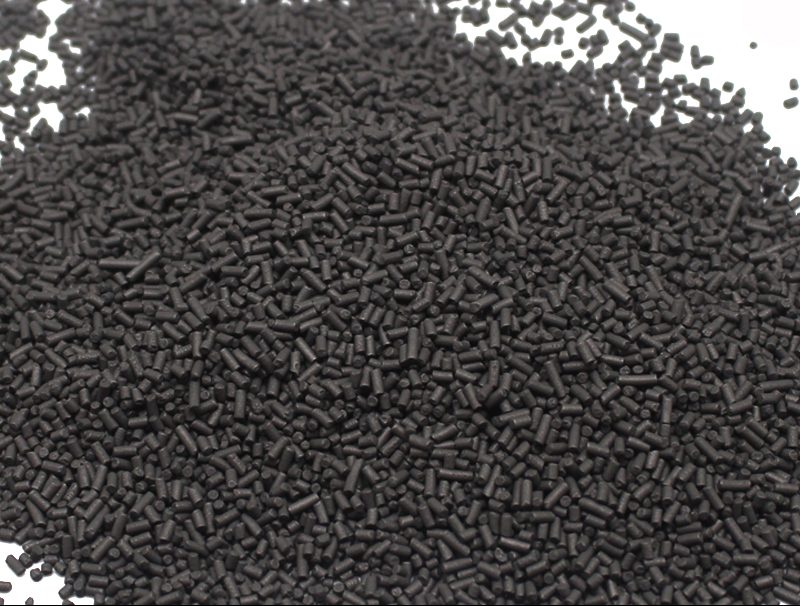

The PSA Process consists of 2 interconnected PSA Towers filled with Carbon Molecular Sieve (CMS) – a carbon-based chemical containing microscopic pores on its surface.

Clean and dry compressed air enters the PSA System. Here, Oxygen molecules are trapped by CMS and only Nitrogen gas molecules proceed further into the On-site Generation process.

PSA based Nitrogen generation is a non-explosive, non-cryogenic method that does not require government permission. Customers save time and effort by avoiding such formal processes.

Nitrogen-rich compressed air enters one PSA tower at a high pressure. Compressed air pressure enables the CMS chemical inside the PSA tower to produce high purity Nitrogen.

The two PSA towers, filled with CMS, are pressurized alternately after 60 seconds. The air pressure swings from Tower 1 to Tower 2 during the time cycle. The swing cycle is necessary to regenerate the CMS since it becomes saturated with Oxygen molecules after 60 seconds.Automatic valves operate the swing process, the valves are tested for several thousand cycles.

Adsorption is a surface level reaction in which molecular pores on the surface of CMS trap Oxygen molecules.Once oxygen molecules are trapped, Nitrogen molecules are free to flow out of the PSA tower.After 60 seconds, Nitrogen generation stops and the oxygen molecules are released to the atmosphere when the pressure swings in the PSA system.

| Gas Composition / Model |

CMS Series Most economic product for commercial grade purity |

HPN Series Trusted partner of major heat treatment and high purity applications |

PDx Series For applications requiring ultra-pure Nitrogen and Nitrogen-Hydrogen gas mixture |

Nitrogen System ‘NS’ Adsorbtech concept for Uninterrupted Nitrogen gas supply |

|---|---|---|---|---|

| Nitrogen | 95.0 to 99.9% | 99.91 to 99.999% or (10 PPM) | 99.99% to 99.9999% or (1 PPM) | 98.0% to 99.9999% (or 1PPM) |

| Oxygen | 5.0 to 0.1% | 0.09 to 0.001% | 0.0009% to 0.0001% | 2% to 0.0001% |

| Hydrogen | Nil | Nil | As per user specification | As per user specification |

| Pressure | 0.5 to 60 kg/cm2g | 0.5 to 60 kg/cm2g | 0.5 to 60 kg/cm2g | 0.5 to 60 kg/cm2g |

| Dew Point | (-) 40 to (-) 50℃ | (-) 51 to (-) 65℃ | (-) 66 to (-) 80℃ | (-) 40 to (-) 80℃ |

| Applications | PRODUCTS | PRODUCTS | PRODUCTS | PRODUCTS |

| Highlights | - Consistent purity - Low running costs - Wide range of applications |

- No Ammonia required - PPM purity directly from compressed air - No.1 choice for major heat treatment applications |

- High safety standards - Ammonia dissociator available - Customized gas composition |

- All models are available in ‘NS’ design - 24*7 Nitrogen supply even in maintenance/breakdown - Hassle-free nitrogen on non-stop basis |

Nitrogen is the lifeline for several applications like precision Furnaces, Reactors, Reflow Ovens, SMT Lines. Both, equipment and material are capital intensive and require stringent supply of Nitrogen gas. NS is an Adsorbtech concept that generates uninterrupted and pure Nitrogen on 24*7*365 basis. ‘NS’ customers experience flawless Nitrogen supply for several years without breakdown.

Save capital by taking Nitrogen Gas on lease.

Adsorbtech Leasing Solutions cut your operational costs and let you focus on your core area of business.

We supply on-site Nitrogen Gas on a monthly basis at a fixed price.

Performance of the CMS chemical improves when fed pure and dry compressed air. Clean air ensures a long life of CMS.

Adsorbtech Compressed Air Treatment ‘CAT’ Technology eliminates particulates like oil, dust and vapor moisture to deliver pure and dry compressed air at usage point.

Reliable and Efficient Solutions for 95.0 to 99.9% purity

Catering to Nitrogen-Ammonia gas mixture requirements

Adsorbtech Innovation for Uninterrupted Nitrogen supply

Trusted solution for Heat Treatment and sensitive applications

Authorized Adsorbtech spare parts for long life and efficiency

Designed for upto 40 Bar pressure

Connect with us and meet your compressed air requirements today